With over three decades of hands-on experience in using and implementing stored product insect (SPI) pheromone traps, I have witnessed firsthand the evolution of SPI pest management practices in the Indian food industry.

My journey began in 1995, when I initiated the first SPI pheromone monitoring programme in India’s food sector while working as a Food Safety Manager at AVT McCormick Ingredients Limited.

In 2002, while working as the head of the quality department at Pest Control (India) Private Limited (PCI), I introduced the Trece, Inc. (Trece) Storgard product range to the Indian pest control industry. I later launched a comprehensive SPI monitoring service using Storgard traps and lures for PCI customers across India.

In 2023, I relaunched the Trece Storgard range through Giridhar Pai Associates LLP, continuing its widespread adoption across the country.

Despite these advancements and decades of widespread use, I routinely encounter common mistakes among SPI pheromone trap users, as revealed in customer interactions and training sessions.

This blog post aims to address the top twelve mistakes Indian users make and offer practical advice to improve your SPI monitoring programme.

- Not Monitoring Stored Product Insects with Pheromone Traps: Many Indian food companies neglect SPI monitoring altogether, failing to track pests such as cigarette beetles (CB), confused and red flour beetles (CFB/RFB), and almond moths (AM). Even processors dealing with less common pests, such as khapra and warehouse beetles (KB/WB), often overlook regular monitoring of them. Such a lack of oversight can result in unchecked infestations, leading to significant product losses and regulatory non-compliance.

- Failing to Establish a Comprehensive Monitoring System: Effective SPI management requires a robust network of traps and lures, tailored for all likely pest species and strategically placed in every area where pests might occur—including storage, processing, and shipping zones. SPI populations are active indoors year-round, so your monitoring system must be continuous and comprehensive to ensure early detection and timely intervention.

- Using SPI Pheromone Traps Only During Audits: It is common for food manufacturers to deploy SPI pheromone traps solely during food safety or regulatory audits, merely to demonstrate compliance. Such a reactive approach undermines the true value of an SPI monitoring programme by missing the opportunity to highlight SPI infestations. Consistent, year-round monitoring is essential for effective SPI pest management and long-term food safety.

- Removing Trapped Insects to Show Zero Counts: At some facilities, pheromone-trap monitoring employees remove trapped insects before audits to display zero pest presence artificially. This practice is misleading and counterproductive, as a zero count is unrealistic in any dry food facility. The presence of SPI adults in traps is not a nonconformity but a valuable tool for the evaluator in SPI pest control decision-making.

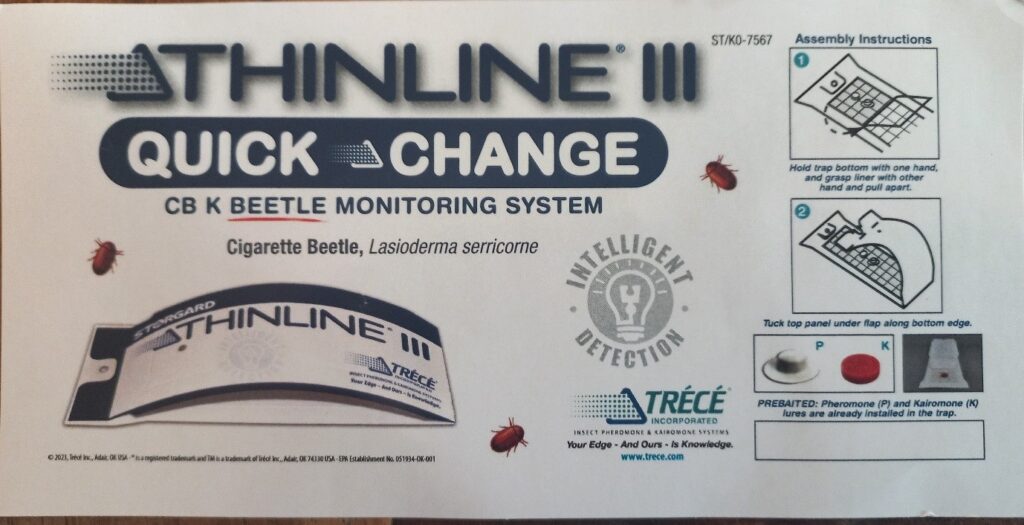

- Ignoring Manufacturer-Recommended Replacement Schedules: Pheromone traps and lures must be replaced at intervals specified by the manufacturer. For instance, the Quick Change Dome Trap requires lure tray replacement every two months, while New Serrico Traps need monthly changes, and CB III Thinline and Storgard II traps should be replaced every two months. Neglecting these schedules diminishes trap effectiveness and can lead to undetected infestations.

- Relying Only on Kairomone Oil for Dome Traps: The original Trece Storgard Dome Trap used both a species-specific pheromone lure and a generic kairomone oil (food attractant). Relying solely on kairomone oil renders the trap ineffective, as pheromones are the key attractant for target beetles. Always use the complete lure combination to maximise catches.

- Not Setting Action Thresholds: Monitoring SPIs in pheromone traps without defined catch thresholds limits the programme’s usefulness. Establish maximum acceptable catches for individual traps, average trap counts in each area, and total catches for spaces. Thresholds must trigger corrective actions when exceeded, enabling timely pest interventions and preventing outbreaks.

- Overlooking In-Transit Monitoring: Pheromone traps are not limited to static storage or processing areas—they can and should be used to monitor goods in transit, such as within trucks or export shipping containers. Traps provide early warning of infestations during transport, helping to safeguard product quality and meet import-export and domestic trade requirements.

- Conducting Daily Trap Counts Unnecessarily: While regular monitoring is important, daily trap counts are seldom necessary. Weekly counts are usually sufficient unless a threshold is exceeded, in which case more frequent monitoring may be warranted. Over-monitoring wastes resources without providing a significant additional benefit.

- Continuing with Obsolete Dome Traps: With the introduction of the Quick Change (QC) Dome Trap in 2013 and its exclusive availability since 2025, Storgard users should transition from the old Dome Trap. The QC Dome offers improved ease of use and higher attraction rates for CB, CFB/RFB, and KB/WB. Persisting with outdated Dome Traps compromises the effectiveness of SPI beetle monitoring.

- Neglecting to Maintain Buffer Stock: Supply chain delays may occasionally affect the availability of imported Storgard and Serrico traps and lures in India. Given the critical nature of SPI monitoring, users should maintain a buffer stock of traps and lures for at least two to four months. Buffer stocks ensure uninterrupted monitoring, even during supply disruptions.

- Failing to Identify Infestation Sources: SPI pheromone monitoring is a diagnostic tool—not just for pest presence, but also for identifying infestation sources. When trap counts exceed thresholds, investigate to locate infested products, equipment, or residues. Effective response may include targeted pest treatments, thorough cleaning, or, in severe cases, product disposal

Conclusion

A robust stored product insect monitoring programme is indispensable for dry food factories. SPIs are natural inhabitants of storage, processing, and transit environments. Since visual detection is difficult and waiting for consumer complaints is far too late, regular pheromone-based monitoring is a non-negotiable aspect of food safety management.

As one of Asia’s leading distributors of SPI pheromone traps and lures, GPA possesses the expertise to help you initiate or optimise your monitoring programme. Reach out to us for professional guidance and let us help you strengthen your business’s protection against SPIs and enhance your food safety standards.