Since September 2020, we have been selling FLYght Traps as a modern, energy-efficient alternative to conventional UV fluorescent tube insect light traps (ILTs).

Much like how electric vehicle manufacturers promote their cars as alternatives to traditional internal combustion engine vehicles, we have positioned FLYght UV LED ILTs as the next generation in pest control.

Over the years, we’ve encountered a range of questions and misconceptions about FLYght Traps, especially from customers new to UV LED technology and our unique trap designs.

In this blog post, we address and counter eight of the most common FLYght Trap misconceptions.

1. “The Trap Is Not Bright Enough”

Many customers equate brightness with effectiveness, assuming that LED-based ILTs should be as bright as traditional tube traps. However, the high brightness of tube ILTs is due to their higher power consumption (often 45W or more), which results in excessive blue and UV light, much more than is necessary to attract flies. Our research has shown that conventional ILTs often waste energy and emit unnecessary light. In contrast, the FLYght One and FLYght Duo use just 8W, while the FLYght Deco uses only 4W. Despite their lower power consumption and reduced light output, our traps perform as well as their higher-wattage counterparts, offering effective fly control without excessive brightness.

2. “The Trap Is Too Small”

FLYght Traps are intentionally compact, thanks to the small size of LEDs and the efficient design of their internal electronics. Our engineers at Pestroniks Innovations Pte. Ltd. (Pestroniks Innovation) have created traps that require only enough space for LEDs and a printed circuit board. Importantly, the trap’s size does not affect its performance. Instead, the compact design allows the traps to fit seamlessly into most environments, making them unobtrusive and convenient for customers.

3. “The Glueboard Has Less Surface Area”

Some believe that the glueboard in FLYght Traps is insufficient compared to those in other traps. FLYght Traps use a universal glueboard, like most other ILTs. While some tube traps use one and a half glueboards, with varying efficiency depending on placement, FLYght Traps are designed primarily for monitoring low fly populations rather than mass trapping flies. The glueboard we have provided is more than adequate for the number of flies typically attracted and captured by the trap over periods of a week to a month.

4. “The Trap Doesn’t Perform as Well as Our Current Trap”

We have encountered customers who test FLYght Traps side-by-side with conventional tube traps and conclude that the latter attracts more flies. However, such comparisons are rarely scientific and lead to misconceptions about FLYght Traps. We advise customers to use our standardised fly catch test for a fair assessment, evaluating each trap individually. Repeated independent laboratory tests have verified that FLYght Traps perform as well as the best tube traps available globally.

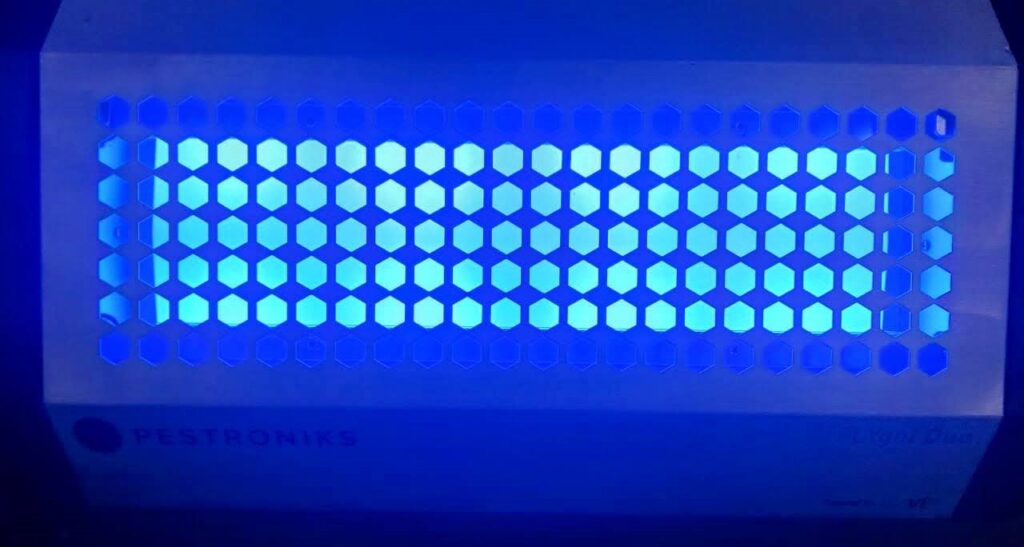

5. “The Trap Has Holes Instead of Slits”

The shape of a trap’s openings is dictated by both design and scientific research. Contrasting surfaces attract flies, and the hexagonal holes in FLYght Traps are specifically designed to maximise this effect, guiding flies toward the glueboard for effective trapping. We review trap opening at the prototype stage and have found that the current hexagonal ones in the FLYght One and FLYght Duo help those traps perform well.

6. “The Trap Is Expensive”

While the initial investment in a FLYght Trap may be higher, its ongoing operating costs are significantly lower than those of tube traps. FLYght Trap LEDs are rated for 50,000 hours (approximately 6.7 years) and consume only 20% of the electricity required by traditional tube traps. Tube traps typically require annual tube replacements and use five times as much electricity. Detailed cost comparisons on our website demonstrate how customers can recoup their investment through energy and maintenance savings over just a few years.

7. “The Trap Doesn’t Work”

Some scepticism arises from customers’ experiences with poorly designed LED traps from other manufacturers. Unlike fluorescent tubes, LEDs emit UV light differently, and not all designs are effective, as we have found in our market survey. At Pestroniks Innovations, we addressed this challenge by incorporating bio-VE+ inserts and using blue glow and reflected UV at optimal intensities and wavelengths to attract flies. Inspired by carnivorous plants, FLYght Traps effectively lure and capture flies on glueboards.

8. “The LEDs May Not Last as Promised”

We’ve sold FLYght Traps since 2020, and many customers continue to use their original units without needing to replace the LEDs after more than 5 years. While we maintain confidentiality regarding our LED supplier, we source components from one of the world’s largest and most reputable LED manufacturers, ensuring long-lasting performance.

We hope this blog post has addressed your questions and clarified any misconceptions about FLYght Traps. From our early prototypes to today’s widely adopted models, our journey from 2020 to 2026 has been marked by innovation and customer satisfaction.

FLYght Traps has earned recognition as the leading UV LED ILT in India, thanks to its superior features, reliable performance, and excellent service support. Food safety auditors have commended FLYght Traps for their effectiveness in fly monitoring, further validating our commitment to quality.

Our supply chain is among the fastest in the pest control industry, with most orders shipped within a day or two via reliable courier services. In six years, incidents of product damage have been minimal, typically resulting from transporter mishandling rather than product faults.

We are equally committed to after-sales service. Most complaints we’ve received have stemmed from mishandling, such as replacing original UV LEDs with non-UV types, water damage causing electronic faults, or improper storage leading to condensation and corrosion. In such cases, we’ve leveraged reverse logistics to retrieve and assess affected units, replacing parts where possible to restore functionality.

At Giridhar Pai Associates LLP (GPA), we take pride in supplying India’s top UV LED Insect Light Trap, the FLYght Trap.

We reaffirm our dedication to product excellence and outstanding service, and we look forward to serving even more customers in 2026 and beyond.