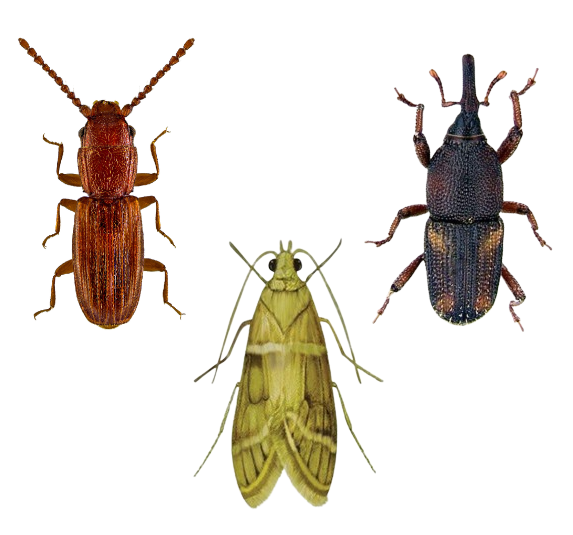

Stored Product Insect Pests

Contamination and Damage: SIPs contaminate food with their excrement, body parts, and webbing, making it unfit for consumption or sale. SIP contamination and damage reduce food quality and market value of products, further adding to economic losses.

Loss of Germination Potential: SIPs damage grain and other seeds, reducing their viability for planting as food crops. Damage to seeds by SIPs directly affects farmers’ seed stock and future crop yields, impacting agricultural productivity and food security.

Global Impact:

- Trade Barriers: SIP infestations can lead to trade restrictions and bans on agricultural exports from affected countries. Such trade restrictions disrupt international trade and create economic hardship for exporting nations.

- Loss of Government Revenue: Reduced agricultural production and trade lead to lower tax revenues for governments, impacting public services and infrastructure development.

- Environmental Impact: Intensive use of pesticides to control SIPs can have negative consequences for human health and the environment. Additionally, food waste due to infestations contributes to increased greenhouse gas emissions.

Economic Burden of SIPs

on Various Stakeholders:

- Farmers: SIPs directly impact farmers' income by reducing yields and market value of their produce. Additionally, they force farmers to incur costs for pest control measures and storage infrastructure to minimize losses from SIPs.

- Food Industry: SIPs cause significant economic losses for grain processors, retailers, and food manufacturers who face costs for pest control, product recalls due to contamination, and quality control measures.

- Consumers: Ultimately, consumers bear the brunt of SIP economic losses through higher food prices due to reduced supply and increased production costs. Losses from SIPs can disproportionately impact low-income populations, exacerbating food insecurity.

Integrated Pest Management (IPM) of Stored Product Insect Pests

Integrated pest management (IPM) is a comprehensive and sustainable approach to controlling stored product insect pests (SIPs).

IPM emphasizes SIP prevention and combines various methods to effectively manage their populations while minimizing environmental and health risks.

Following are the key elements of an IPM program for SIPs:

1. Monitoring:

Regularly inspect stored products for signs of infestation, such as live insects, insect damage, and frass (insect excrement). Use pheromone and sticky traps to monitor adult insect activity and identify specific pest species. Conduct grain temperature and moisture measurements to identify conditions conducive to pest development.

2. Sanitation:

Cleanliness: Regularly clean storage areas, including floors, walls, and equipment, to remove food debris and residues that attract pests.

Waste Management: Dispose infested products and waste materials properly to prevent them becoming a source of SIP spread.

Sealing: Seal cracks and openings in storage structures to prevent SIP entry and harbourage.

3. Physical Control:

Temperature Control: Store commodities at cool temperatures (below 15°C) to slow down insect development and reproduction.

Modified Atmosphere Storage: Deplete oxygen and/or enrich carbon dioxide levels in storage to create an atmosphere that suffocates insects.

Hermetic Storage: Store products in airtight containers to prevent insect entry.

4. Chemical Control:

Use insecticides registered for SIPs only as a last resort and per label instructions. Rotate different insecticide classes to prevent the development of resistance.

5. Good Agricultural Practices:

Harvest and store crops with proper moisture content to minimize spoilage and attracting SIPs. Use clean and pest-free containers for storage. Maintain good hygiene practices in production, storage and the rest of the supply chain.

Benefits of IPM in SIP management:

- Reduced reliance on chemical pesticides.

- Lower environmental impact.

- Improved food safety.

- Long-term cost-effectiveness.

- Sustainable pest management solution.

Monitoring Stored Product Insect Pests Through Pheromone Traps

Stored Product Insect Pests (SIPs) seriously threaten food stores, warehouses, and where grains, dried fruit, and other dry food products are stored. SIPs cause millions of dollars of damage through contamination and infestation, leading to food waste. Early SIP detection and management are crucial to limit their damage, and that’s where pheromone traps come into play as an aid.

What are Pheromones?

Pheromones are chemicals insects secrete to communicate with each other within an insect species. Pheromones can trigger behaviours like attracting mates, signalling aggregation, alerting of a food source or warning of danger. As scientists have isolated and synthesized many SIP pheromones, they can be used to monitor and control SIPs.

Types of Pheromone Traps for Stored Product Insect Pests

- Sex Pheromone Traps: These traps use female sex pheromones to attract males of specific SIP and are useful for monitoring and determining an infestation’s presence and relative size. Short-lived SIPs secrete sex pheromones that aid the female and male in finding each other for mating and perpetuating their species. Examples include traps with the sex pheromones for the almond moth, webbing clothes moth, cigarette beetle, khapra beetle, and warehouse beetle. Sex pheromones are available for a limited number of SIPs.

- Aggregation Pheromone Traps: These traps use pheromones that attract males and females for a wider range of species. Aggregation pheromones may be secreted either by female or male insects, and they indicate the presence of food or harborage in other members of the species. Aggregation pheromones are less effective than sex pheromones as SIPs occur in foods and thus may not elicit the desired response to adult SIPs infesting a food product. However, they’re useful for detecting the presence of low SIP populations of confused and red flour beetle, lesser and larger grain borer, rice weevil and casemaking moth.

- Combination Traps: These often combine pheromones with kairomones or food attractants to increase their effectiveness. They offer a more comprehensive monitoring solution than just pheromone traps, available through popular SIP pheromone trap manufacturers. Using multiple attractants makes combination traps a better option than pheromone traps.

Trap Designs

- Tent/Diamond Traps: Glue-based traps that hang in a tent shape are designed to catch flying SIPs such as almond moths and cigarette beetles.

- Pitfall Traps: These are floor-placed traps with covers to protect the pitfall and hold the pheromone. The pheromone lures in the trap attract SIPs, which crawl inside and become trapped in the kairomone oil used as a second attractant. The Trece Inc. Storgard Dome trap is a popular pitfall for monitoring cigarette beetles, confused and red flour beetles, khapra and warehouse beetles, and lesser and larger grain borers.

Benefits of Pheromone Traps

- Sensitive and Targeted: Pheromone traps can detect even low-level infestations of target species, allowing early intervention. Visual inspections for SIP detection may be ineffective if the population is low and if the insects are inside the food they have infested.

- Reduces Reliance on Pesticides: Effective SIP monitoring by pheromone traps enables strategic management, reducing unnecessary pesticide use. Pesticide sprays and fumigants can be used when SIPs are detected and exceed set thresholds.

- User-Friendly: SIP pheromone traps are easy to install and monitor without special equipment or extensive user training.

- Cost-Effective: Pheromone traps offer a relatively inexpensive way to stay ahead of SIP problems, which can be costly if unattended and lead to infestation that could lead to extensive product damage and losses.

Limitations of Pheromone Traps

- Species-Specific: Most pheromone traps attract only one or a few closely related species, making it necessary to use a combination of traps. However, some manufacturers like Trece, Inc. now offer ultra-combi traps that allow for monitoring multiple beetle species or even a combination of moths and beetles.

- Not a Stand-Alone Control Method: While helpful in SIP management, pheromone traps don’t directly eliminate infestations but help track fluctuating insect populations by season. Effective sanitation, product inspection, inventory rotation and other SIP control strategies remain essential even when using an SIP pheromone monitoring programme.

The Role of Pheromone Traps in SIP Management

Pheromone traps play an essential role in the Integrated Pest Management (IPM) of SIPs:

1.Early Detection: Regular monitoring with pheromone traps allows for swift detection of SIP activity, enabling proactive measures.

2.Pinpointing Infestations: Traps can help to identify zones harbouring specific SIP species, directing targeted control efforts for greater efficiency.

3.Evaluation of Control Measures: Monitoring pheromone trap catches before and after interventions such as cleaning, heat treatment, or fumigation helps assess the effectiveness of those measures.

Staying Ahead of Stored Product Insect Pests

Food companies don’t need to be hostage to Stored Product Insect Pest attacks on their products. SIP Pheromone traps provide an effective way to stay one step ahead. The Storgard range of SIP pheromone traps and lures is a leading global choice in managing Stored Product Insect Pests. It is now available in India through Giridhar Pai Associates LLP.