In the complex world of the food industry, decision-making can often become a prolonged process, especially when it comes to implementing essential food safety measures.

A recent experience with a reseller highlighted the risks associated with delays in purchasing critical monitoring systems, particularly for pests such as cigarette beetles.

This cautionary tale offers insight into the potential consequences of indecision and the urgent need for proactive food safety management.

Three months ago, we received an inquiry from a reseller about the immediate need for New Serrico Traps.

A food industry customer in this reseller’s territory had initially shown interest in ordering these effective traps but hesitated upon learning about the associated costs and minimum order quantities.

Despite our thorough follow-up, it became evident that the customer did not reach a final decision, leaving their facilities potentially vulnerable to cigarette beetle infestation.

Last week, we received a panicked call from the same customer, seeking immediate advice on how to monitor and control a cigarette beetle (CB) infestation that had likely compromised their product safety.

Our Managing Partner, Giridhar Pai, an expert with over thirty years of experience in pest management, spent over half an hour discussing the serious complexities surrounding CB control.

He emphasised the critical importance of pheromone traps in identifying ongoing infestations and stressed the need for taking proactive measures to mitigate trap counts in the forthcoming weeks.

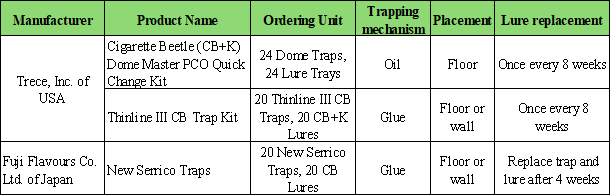

In response, we provided detailed information about Giridhar Pai Associates’ (GPA) cigarette beetle pheromone traps, which included a comparative table highlighting three distinct products:

- Japan’s Fuji Flavours Co. Ltd.’s New Serrico Trap

- The Storgard Quick Change CB+K Dome Trap from Trece, Inc., USA

- Trece, Inc.’s Thinline III CB+K Trap

A Comparison of Storgard Cigarette Beetle Dome Master PCO Quick Change Kit, Storgard Thinline III CB Trap Kit and Ecomone New Serrico Traps

However, much to our surprise, there was silence on the customer’s part for ten days after our proposal.

When I finally reached out, I learned that the customer was now considering using UV light systems for cigarette beetle monitoring.

By the end of that day, I managed to speak with both the local customer representative and their overseas colleague.

I advised them on the necessary steps for effective CB management within their facility, though it was evident that their situation required urgent attention.

The overseas colleague expressed interest in sourcing Storgard traps to evaluate their effectiveness, with plans to economise on monitoring by switching to pheromone traps afterwards.

The customer indecision mentioned above struck me as puzzling.

After more than twelve weeks since their initial inquiry about cigarette beetle monitoring tools, the customer—a business operating in plant-based products and facing apparent infestation—was only beginning their research into potential solutions.

Such a delay was concerning, as cigarette beetles can cycle through multiple generations in just a few weeks.

During this time, they could infest raw materials, in-process goods, finished products, and even equipment, leading to widespread contamination.

If action is not taken promptly, businesses like this one may soon face a severe cigarette beetle infestation within their premises.

Our experience with this customer reflects a broader trend throughout the food industry, where decision-making processes can be alarmingly slow when it comes to cigarette beetle management.

The presence of cigarette beetles and other polyphagous stored product insects (SPIs) should serve as a significant warning signal.

Without proper monitoring and management in place, these pests pose a considerable threat to food safety, potentially impacting countless consumers.

Graphic highlighting Because Cigarette Beetles Don’t Wait for Approval

It is alarming to note the extent to which food quality and safety managers may underestimate the damage potential posed by cigarette beetles.

Throughout our discussions, I deduced that their imported raw materials from Europe may have introduced this pest into their supply chain.

Once these beetles are in, they not only cause damage to products but also multiply quickly and can spread throughout a facility. These nocturnal insects are adept at navigating any establishment, reaching food products or equipment hidden away in corners.

Inevitably, companies grappling with cigarette beetle infestation will turn to GPA for help with monitoring through pheromone traps.

However, such compromised situations and the consequent need for urgent resolutions could often be avoided if organisations chose to act promptly rather than waiting for approval to move forward with necessary cigarette beetle management systems.

To bolster your company’s defence against cigarette beetles, we suggest the following key points for monitoring and management in food, tobacco, and related industries, including institutions like museums that may also face cigarette beetle infestations:

1. Check for Susceptibility to Infestation:

Recognize the wide variety of items that cigarette beetles feed on, including:

– Tobacco products (cigars, cigarettes, loose-leaf tobacco)

– Grains and cereals (such as flour, rice, and pasta)

– Spices and dried herbs (e.g., ginger, turmeric, coriander, paprika)

– Dried fruits and nuts (like raisins, walnuts, almonds)

– Processed food (including breakfast cereals and dry instant noodles)

– Pet food and animal products (e.g., dried fish, animal meal)

– Miscellaneous items (such as pyrethrum powder and bookbinding materials)

– Pharmaceuticals (such as crude drugs)

2. Look for Signs of Infestation:

Be vigilant and check for:

– Small, light-colored, C-shaped larvae

– Adult beetles, which are small and reddish-brown

– Product damage, including holes in packaging

– Webbing or frass (larvae droppings)

– Pheromone trap catches

3. What to Do After Identifying Infestation:

– Discard any infested items to prevent the spread of cigarette beetles.

– Thoroughly clean affected areas.

– Inspect areas behind appliances or in hidden corners for any lingering signs of infestation.

– Use insecticides specifically labelled for treatment against cigarette beetles.

– Set up pheromone traps for ongoing monitoring and post-monitoring steps.

4. Cigarette Beetle Prevention is Key:

– Store all dried goods in airtight, sealed containers.

– Conduct regular inspections to catch early signs of cigarette beetle infestation of dry foods in paper and plastic packaging, through which cigarette beetle larvae can chew.

– For small quantities of foods, consider temperature treatments—heating to 125°F for several hours or freezing to 0°F for a few days can eliminate cigarette beetles.

In conclusion, this cautionary tale serves to illustrate the critical role that timely decision-making plays in safeguarding food safety from cigarette beetles.

As we’ve elaborated, the cost of implementing cigarette beetle pheromone traps is minimal when compared to potential losses from product damage and reputational harm from cigarette beetle infestation of consumer products.

We encourage you to take immediate action to prevent the presence of the cigarette beetle from compromising your food safety.

If you’re looking to initiate a monitoring program for cigarette beetles, feel free to Contact Us through our website.

Your proactive steps today pave the way for a safer food supply tomorrow, free of cigarette beetles.